We often the term “localisation” a lot these days. The primary reason for that is that it relates directly to the cost of the vehicle as well as the governments’ Make in India initiative. The aim of this initiative is that any vehicle in India should contain maximum components that have been manufactured in India itself. In other words, there should be the least number of components for which we have to depend on foreign imports. This would ideally reduce our dependence on the other countries and promote our own companies and economy. A perfect example to understand the importance of localization is the current shortage of semiconductors that the world and the automobile industry are facing at the moment. Because we rely heavily on imports for semiconductors, our production is getting affected at the moment. In fact, it has caused a delay in the launch of some products in India.

Also read: India will become number one auto manufacturing hub in the next five years – Nitin Gadkari!

We had recently reported about Mahindra suffering from this shortage and therefore, the launches of next-gen Scorpio and XUV500 getting delayed a bit. As a result, Nitin Gadkari, the Union Minister of Road, Transport and Highway has publically announced that the companies should focus their attention on more localisation. Gadkari requested the vehicle and component manufacturers to take localisation seriously or the government will have to think about hiking import duties on automotive components. This will further increase the costs of vehicles and in turn, might affect the recovery path of the industry. The increase in prices is the only way to discourage importing from outside the country. Additionally, the Vehicle Scrappage Policy will also contribute towards getting rid of old and pollution-causing vehicles and promote purchasing of new vehicles. All these steps combined will prove to be the deciding factors for the Indian automobile industry to recover and grow rapidly.

Also read: Vehicle Scrappage Policy will increase jobs and reduce costs of new vehicles!

Need for Localisation

We have already seen that the next product of Skoda, the Kushaq has achieved around 90% localisation ill now but Skoda is trying to take this number up to 93-95% by the time the Kushaq is production-ready. This shows Skoda’s intent and commitment towards achieving high levels of localisation. The same is the case with the newest player in India, Citroen. They had recently unveiled the luxury mid-size SUV in C5 Aircross which was a CKD unit assembled in India. But the second product, which will be mass market and fall under the compact SUV segment category, will be highly localised to keep costs in check as well as contributing towards the government’s “Make in India” initiative.

Lastly, Jeep is also following the same path as the Citroen. Ever since the formation of Stellantis, Jeep might be able to make use of Citroen’s platform to manufacture a compact SUV in India. The key highlight of that model will be localisation to keep the prices competitive. Jeep has already started local assembly of its Wrangler SUV in India recently and the new Grand Cherokee will also be assembled in India. VW will also take advantage of its MQB A0 IN platform to power its upcoming Kushaq sibling, the Taigun and try for higher localisation levels.

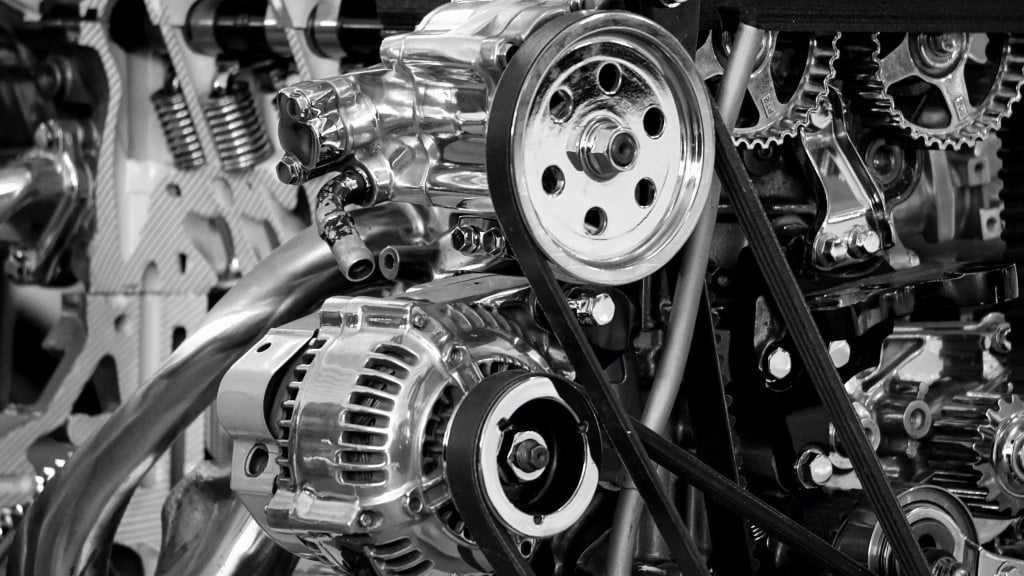

Image Credit: Pexels