Here we are again, with another post related to automobile technology. The aim of these articles is to share the knowledge of automobile technologies in simple words so that you get a fair idea of how any particular engine component or technique works in a vehicle. That is the reason, we pick out the most complex but relevant topics and simplify for everyone’s understanding. The topic we’ve picked today has to do with petrol powertrains and is a very common phenomenon called Knocking. So, what is knocking? How is it caused? What are its consequences and how can we prevent it? These are some of the questions our article will be revolving around. So let’s dive into it.

Also read: Types of Ignition – Spark, Compression HCCI and SPCCI Ignition!

Engine Ignition Timing

We have learnt in some of the previous tech articles that there are four strokes to an engine. For the petrol engines, just before the end of the compression stroke, the spark plug ignites the air-fuel mixture, compressed inside the cylinder of the engine. After having been ignited, there is an explosion of energy. This is a result of the conversion of the chemical energy of the petrol into mechanical energy which makes the car move. The explosion causes pressure onto the piston, making it move downward. This is called the power stroke as well.

Also read: Types of Suspension setups – MacPherson Strut, Double Wishbone and Leaf Spring!

Arguably, this is the most important stroke in the combustion cycle. Depending upon how well the combustion occurs, all the factors are influenced by it. This includes the emissions, power and torque output, fuel consumption and safety of the engine and its components. So, the timing of the ignition is of paramount importance. The timing is controlled by the ECU (Engine Control Unit) of the vehicle which sends out signals to carry out the necessary operations. It receives inputs from various sensors and takes a look at what the driver wants from the steering angles, vehicle speed and throttle inputs. Accordingly, it regulates and alters the air/fuel intake or decides the timing of the ignition and performs many such important tasks. It is also referred to as the brain of the vehicle.

That means for every situation the car is in, there is a certain specific time when the spark plug will ignite the air-fuel mixture inside the cylinder of the engine. Every different point of ignition has different consequences in terms of engine performance (power and torque output), efficiency and emissions.

Also read: What are Catalytic Converters? How do they reduce emissions?

Engine Knock

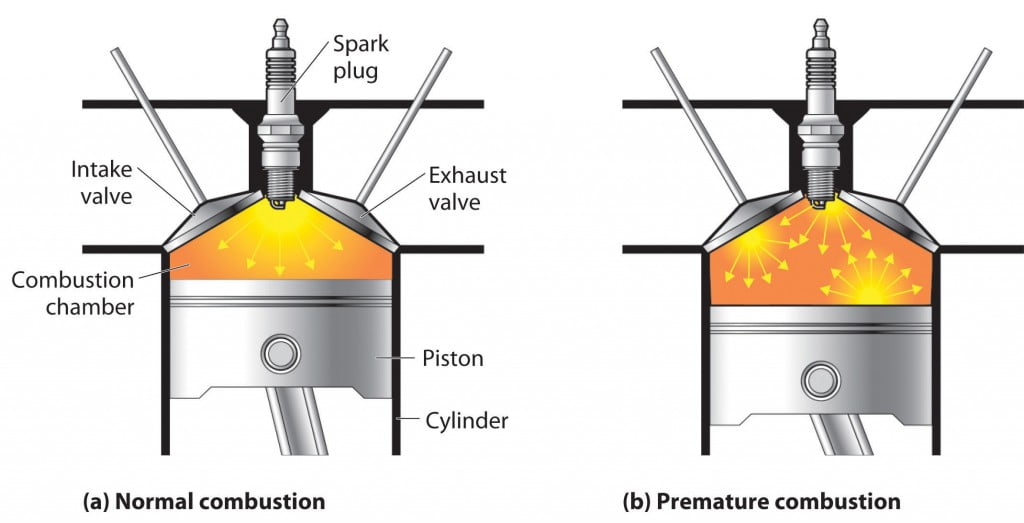

Ideally the early the ignition timing, the more the power and torque output. This translates to better performance, That is why all the new technologies aim at advancing the timing of ignition to make more power and enhance performance. If the ignition takes place late, that means that the piston might already start moving downward and the effect of the combustion will not be that effective. This means that the efficiency will suffer and a lot of work and energy produced by burning fuel will go to waste. That is why there has to be a balance between the two. Another aspect is when the temperature and pressure inside the cylinder get too high due to compression alone. Then the air-fuel mixture might catch fire automatically even before the spark plug ignites the mixture. This is what is referred to as Engine Knock. When the mixture ignites prematurely in some pockets of the cylinder due to high-temperature and pressure. This is an unwanted explosion of air-fuel mixture and can cause severe damage to the engine components. It will definitely affect the efficiency of the engine and might cause pistons to get damaged. That is why the ECU plays an important role in adjusting the ignition timing in such a way that the performance, efficiency and emissions are all taken care of.

Also read: How does Variable Valve Timing affect performance and efficiency?

How to prevent engine knock?

Modern engines have a ton of electronic components. One of these is the knock sensor. The spontaneous automatic explosions in various parts inside the cylinder cause an unusual noise that can be caught by the sensors. There are several ways to prevent engines from knocking. Let us take a look at some of them in detail.

Retard Ignition Timing

Once the knock sensor receives the signal that knocking has started inside the cylinder, it sends the signal to the ECU. The ECU commands the spark plug to retard the timing of the ignition. Therefore, the ignition takes place at a bit later stage and the high pressure and temperature are avoided. One must understand that all these functions take place in milliseconds due to electronic control. In this way, the combustion cycle continues and the knocking is gone with the self-correcting mechanism of the ECU.

Also read: What are Engine Remapping, Calibration and Tuning? Should you remap your car?

High Octane Fuel

You must’ve heard about high octane fuel and wondered what is the actual use of spending extra on premium fuel. Well, the reason is here. The high octane fuel refers to the fuel which is more resistant to engine knock. That means that it does not easily catch fire and high temperature and pressure. This is an extremely important property for petrol to have that it should get ignited only from the spark plug. Using the knock-resisting fuel type will make sure that even if the ignition timing is advanced, the air-fuel mixture will not burn so easily.

Also read: Types of Clutches – Wet, Dry, Single-plate and multi-plate – Pros and Cons!

Lower Compression Ratio

This technique is a bit counter-intuitive in that the compression ratio is directly proportional to the efficiency and performance of an internal combustion engine. The higher the compression ratio, the more efficient the engine is and the better performance is the result. But higher compression ratio also makes the engine vulnerable to knock. That is the inherent characteristic of knock. That is why the role of ECU in determining the exact ignition timing across the entire range of engine operation is so important and difficult without electronic control. The OEMs generally have the perfect balance of the ignition timing for a particular octane fuel where the engine performs well, is efficient and avoids running into engine knock.

Also read: Types of Turbochargers – VGT, Twin-Scroll, Twin-Turbo, Sequential Turbo, E-Turbo!

Low Cylinder Temperature

We know that the auto-ignition of the air-fuel mixture inside the cylinder takes place due to an increase in temperature. Therefore, it becomes extremely important that we don’t allow the temperatures inside the cylinder to rise too much. This means that proper cooling around the cylinder has to take place. The walls of the cylinder should not remain hot otherwise the air-fuel mixture might get detonated as soon as it comes in contact with hot cylinder walls. Also, the intake air should be cool, which is generally done by the air cooler in bigger engines.

Also read: What is Gasoline Direct Injection? Why is it relevant in modern cars?

All these factors can control the auto-ignition inside the cylinder which prevents knocking. It is imperative to prevent this to safeguard the engine components and ensure the long life of the mechanical components of the engine. Also, to ensure the efficient operation of the engine, knocking must be avoided at all costs.

We hope that the concept of engine knocking is clear to you through this post. We will find another important topic for the next edition of the automobile technology article. Until then, stay tuned to Car Blog India and all the Automobile Technology topics.

Image Source: Selimlawrence.wordpress