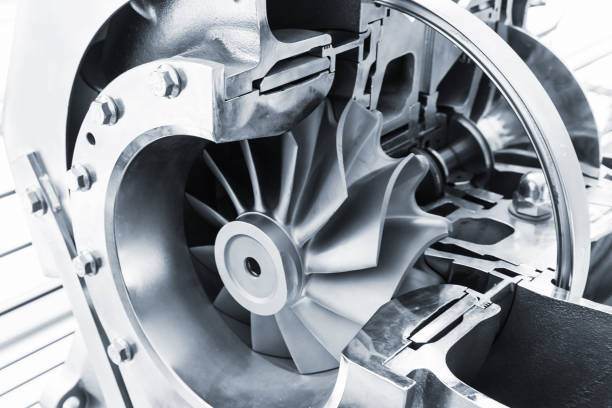

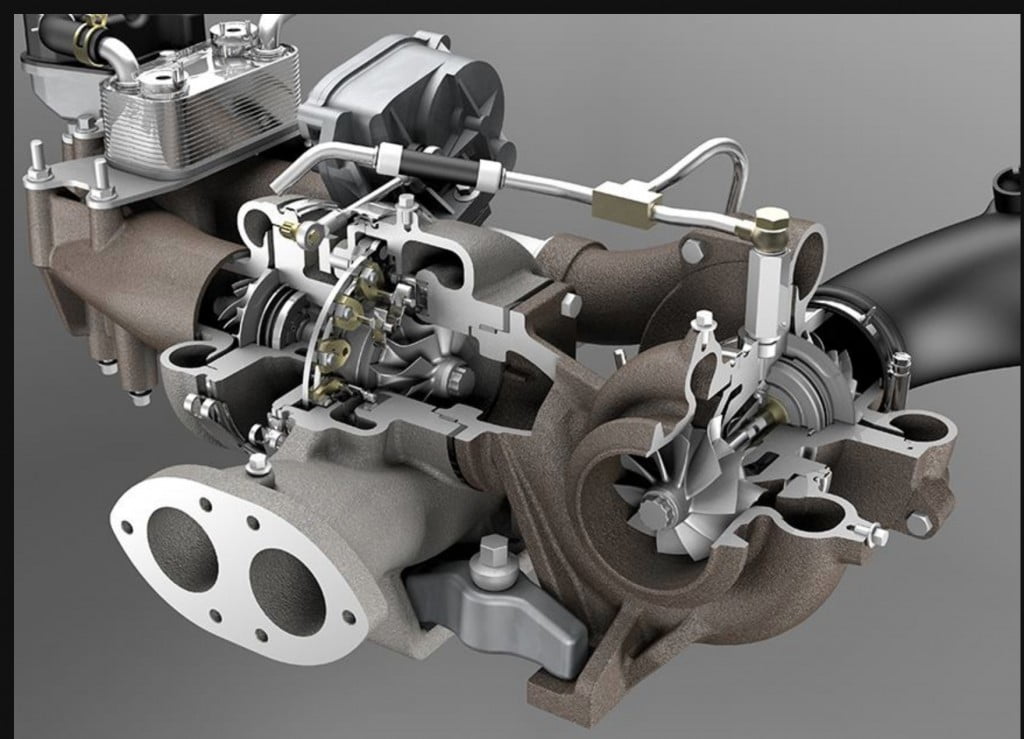

Turbocharging technology has been evolving for a long time now. The traditional objective of a turbocharger is to provide a boost for quick acceleration. This is done because a lot of burnt air-fuel mixture comes out of the exhaust side of the cylinder of your car. Typically, the efficiency at which a petrol internal combustion engine works is a mere 25-30%. Around 30-35% of the energy of your fuel is lost in the form of heat. The other 35% of the energy in the exhaust gases can be reused to improve the efficiency of an ICE. This is done by attaching a turbocharger at the exhaust end of the cylinder. The turbocharger consists of a turbine and a compressor mounted on the same shaft. Now, when the exhaust gases with energy come there, they help in providing force to make the turbine rotate. The rotating turbine rotates the compressor with it. The compressor allows the engine to suck in more air into the cylinder. The ECU of the car senses the extra air from the air-flow sensors and signals for more fuel to be injected into the cylinder. Resultantly, more power is produced and quicker accelerations are achieved due to a sudden boost of the power.

Also read: Types of Clutches – Dry, Wet, Single-plate and Multi-plate – Advantages and Disadvantages of each!

Turbo Lag

Now, we have understood that the turbine is rotated by the amount of exhaust gases. But the main challenge lies in the phenomenon called “Turbo-lag”. What this essentially refers to is the time difference between pressing the accelerator pedal and actually receiving the boost. This happens at low speeds or low engine RPMs because at low speeds/RPMs there is not enough exhaust flow to rotate the turbine. To tackle this issue, a lot of technology has gone into developing various types/combinations of turbochargers. That is what are going to be looking at in the subsequent sections of this post.

Also read: Gasoline Direct injection Technology – Why is it relevant in modern engines!

VGT – Variable Geometry Turbine Turbo Charger

Since we’ve already explained the working of a regular turbocharger, we can now look at the first variant of the turbocharger, the VGT. As the name suggests, the blades inside this turbocharger can mechanically change the effective diameter of the turbine. This helps in scenarios where the flow rate of the exhaust gases is low or high. In the case of low flow rate/low RPMs, the blades close up so that the size of the turbine decreases. When the turbine becomes smaller, it can be rotated even by a low flow rate and the purpose of spooling up the turbo is achieved. When the RPMs increase, the blades open up and the complete diameter of the turbine is exposed. This effectively means that the size of the turbocharger increases. The effects of the turbocharger will be experienced at a wider range of RPM levels. This helps counter the effect of turbo-lag to some extent. VGTs are used in low-cost operations and don’t require complex maintenance, space or installation.

Also read: All you need to know about 4WD and AWD Systems – What is a differential?

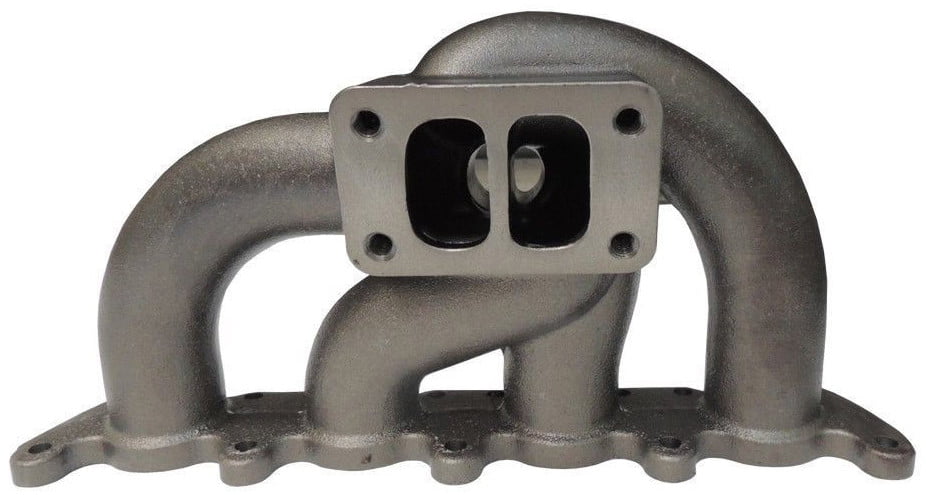

Twin-Scroll Turbo Charger

This is a special type of turbocharging technique used to maximize channeling the exhaust gas energy. In a way, it is designed to serve the same purpose as that of the VGT, i.e., to maximize the RPM range and make the turbo work even in low RPM operations. In this case, the inside of the turbine housing is divided into two segments via a flap that can be opened and closed depending on the requirement. During low RPMs, when there isn’t much air-flow, all the gases are directed towards a single port and it generates enough force to rotate the turbine despite low overall flow. This happens because the area is reduced and hence, the force exerted in a smaller area is increased. When the speeds increase, the flap opens up both sides of the turbo and it starts acting as a regular turbocharger. The main advantage of this kind of setup is that it does the work of two turbos but takes the space of just one. Also, using a single turbo means the weight is less and the engine and fuel will be more efficient.

Also read: Battle of transmissions – Manual vs CVT vs AMT vs DCT vs iMT vs Torque Converter!

Twin-Turbo Charger

As the name suggests, there are two turbos attached to the exhaust side of the cylinder. There can be multiple arrangements for the two turbochargers. For example, Series, Parallel or Sequential arrangements. Let us start with the sequential turbocharging arrangements.

Sequential Turbo Charging

In this arrangement, the two turbos are of different sizes. The small turbo is used in the low RPM scenarios when the exhaust gas flow is low. Being smaller in size it doesn’t require too much flow in order for the turbine to rotate. Hence, it is effective in eliminating the low-end turbo-lag. However, once the RPMs are high enough this turbocharger reaches its mechanical limitations and the operation is shifted to the bigger turbocharger. During the mid RPM range, the bigger turbocharger works to keep the boost going. When the RPMs are very high, both these turbos start working together simultaneously to maximize the boost. This is a very complex construction and mechanism and therefore, is only found in high-end luxury and performance cars. The main advantage of this type of arrangement is an extremely wide range of RPM is covered.

Also read: Types of Suspension Setups – MacPherson Strut, Double Wishbone, Leaf Springs – Pros and Cons!

Parallel Turbo Charging

Then we have the parallel arrangement of the two turbos. This is relevant in the case of more cylinders like V8 or V10 or V12 where we have two cylinder banks. It becomes difficult to manage connections for the turbo and intake manifold when too many cylinders are attached to the same turbo. Hence, two turbos are connected to the two-cylinder banks and the same function is achieved.

Series Turbo Charging

The series arrangement is generally used in airplanes where turbos are connected to each other and high levels of air compression are needed.

Also read: Importance of Downsizing and Turbocharging in modern cars!

Twin-Scroll Variable Turbo Charger

As the name suggests, it combines the functionality of VGT and twin-scroll turbo into one. The operation and working are the same as the Twin-scroll, but it is further flexible because of the changing size of the turbine. The responses are sharper and all sorts of engine RPMs have some kind of boost from this combination during all times. It just improves the flexibility even further and hence, found in performance cars only.

Electrically-Assisted Turbo Charger

In this day and age, almost all the components in a vehicle are in some way assisted by electronic components. Turbocharging technique is no exception. With so much electronic equipment like sensors, actuators, ECUs, semiconductors and other communication between various parts of a car, the need to include a mild hybrid setup is necessary. This is the reason why so many modern cars come with a 48V mild-hybrid setup. The battery pack is used in rotating the turbine at low speeds when there is not enough force to rotate the turbine. Hence, the need for multiple turbos is reduced (at least when it is not a seriously performance-oriented car). The electric motor helps spool up turbo faster at low speeds and then can be switched off. Then there is enough gas flow at high RPMs to carry on the turbo operation.

Also read: Why choosing the right tyre is important and easy!

These are some of the most widely used turbocharging techniques in cars today. Depending on the level of performance needed, affordability, complexity and maintenance, any one or combination of these turbos are used in cars. We hope that you got a thorough insight into the automobile technology followed in turbos these days and why it is important. Stay tuned to Car Blog India for more automobile technology content.

Image Credit: Istockphoto , Mechanical Engg.com , X-Engineer.org