We have got a very important and interesting theme in this post of the automobile technology. For all the people wondering about what actually happens inside an engine, we will try to explain the chemistry and processes behind how power is produced by an internal combustion engine. Also, how important is the phenomenon of ignition to influence efficiency, mileage, emissions and performance (power and torque), we will find out through the course of this article. So, without any further ado, let’s dive into the technology of it all.

Also read: What are Catalytic Converters? How do they reduce emissions?

Ignition – Principle

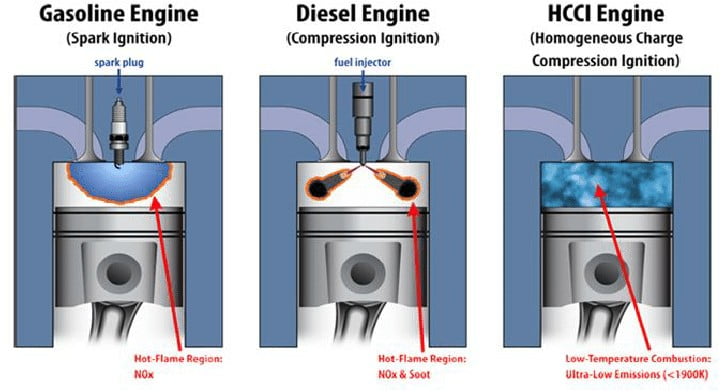

Ignition refers to that procedure in an internal combustion engine, which ignites/burns the air-fuel mixture inside the cylinder of the engine. Once the air-fuel mixture burns, it releases energy that was stored in the fuel and this energy causes the piston inside the cylinder to move downward. That is known as the expansion or the power stroke. It is called that because this is actually the part where the energy from fuel is converted into mechanical energy which propels the car forward. The pistons are connected to the crankshaft, which is in turn connected to the axles/wheels of the car. The purpose of ignition, therefore, is to ignite the fuel (petrol or diesel) to produce power. Depending on the kind of engine (petrol or diesel) there are two types of ignitions: Spark Ignition (SI) or Compression Ignition (CI). There is another type of ignition which we will discuss later.

Also read: Variable Valve Timing – Effects on efficiency and performance!

Spark Ignition

Spark Ignition is something that we observe in the petrol engines only. What this refers to is that there is an external source that causes the air-fuel mixture to burn. In the case of petrol powertrains, this is called a Spark Plug. When the piston is at the bottom dead centre and has sucked in the fresh air from outside into the cylinder, the compression stroke starts to happen. In the compression stroke, the piston will travel upward and compress the air and fuel that is present inside the cylinder. In the case of a port injection system, the fuel is sprayed into the intake manifold itself and by the time the mixture reaches the cylinder, it is thoroughly mixed. This is referred to as a homogenous mixture. Therefore, the piston compresses the mixture and the mixing is even more thorough, which results in better combustion. In the case of direct injection systems, the fuel is sprayed directly into the cylinder. There is not enough time for air and fuel to mix thoroughly. It has other benefits like internal cooling of the cylinder and better control on the amount of fuel sprayed and much more.

Also read: Components of exhaust gas system – Exhaust Scavenging!

The main part comes once the piston reaches the top dead centre and the entire air-fuel mixture is compressed. The spark plugs cause a high voltage current, which ignites the air-fuel mixture and an explosion occurs. This result in releasing of high energy due to chemical reaction and the high pressure causes the piston to move downward, making the vehicle move forward. This is how the spark ignition works. Once the mixture starts burning, the flame front from the explosion causes the entire mixture to burn instantly. However, the flame front is also a region of extremely high cylinder temperature and pressure. This is the part where the oxides of nitrogen form and cause high toxic emissions. These emissions are taken care of by the three-way catalytic converter which works at 90% efficiency. However, the petrol engines are not very fuel-efficient compared to their diesel counterparts.

Also read: Types of turbochargers – VGT, Twin-Scroll, Twin-Turbo, Sequential Turbo and E-Turbos!

Compression Ignition

As the name suggests, in this method the air-fuel mixture is ignited with the help of high temperature and pressure due to compression alone. In fact, the air is the only gas that is compressed here to such a high pressure that the resulting temperature causes the fuel to burn immediately after it is sprayed into the cylinder. This process takes place in the diesel powertrains and there is no external source of ignition. Also, there is no mixing of an air-fuel mixture here. The compressed air is so hot just because of the compression that as soon as the diesel fuel comes in contact with this air, it explodes. Therefore, the timing of the ignition is controlled by the timing of diesel injection into the cylinder.

Also read: Types of Suspensions – MacPherson Strut, Double Wishbone and Leaf Springs!

The diesel engines are very fuel-efficient but are not good for emissions. There are a lot of particle and NOx emissions due to the combustion process. With the new emissions regulations coming into effect almost every year, it is becoming more and more expensive to develop technology to control the emissions from diesel engines. That is the reason why there has been another type of ignition process in development, which is trying to achieve the best of both worlds. This is called the Homogenous Charge Compression Ignition (HCCI) and Spark Plug Controlled Compression Ignition (SPCCI). These are essentially the modern technologies to combat the emissions from the vehicle for the future until electric cars take over completely. This reflects the transition phases from internal combustion engines to electric powertrains.

Also read: What are engine remapping, calibration and tuning? Should you remap your car?

Homogenous Charge Compression Ignition (HCCI)

If you have followed everything till here, then you might already guess the basic principle behind this technology. This technology essentially combines the principles of both the powertrains. The air-fuel mixture is mixed before the compression stroke starts, like in the petrol engines but the ignition takes place because of the compression pressure and temperatures, as in the case of diesel engines. What this results in is high thermal and fuel efficiency with low emissions. This combines the fuel efficiency of the diesel engines and lower emissions of the petrol engines.

Also read: Types of Clutches – Dry, Wet, Single-plate and Multi-plate – Pros and Cons!

In theory, this sounds cool and effective, but in practice, it is extremely difficult to control the timing of when the air-fuel mixture burns. The problem is that if it burns before the compression stroke has occurred, it hinders complete compression and there might not be enough mixing of the air-fuel. This will definitely cause problems to the pistons and may even damage the components. On the other hand, if the mixture burns after the compression stroke, then you have already lost the effectiveness of the ignition and the piston is already halfway down the cylinder. The work/power from the explosion is wasted. To have total control over the compression ignition is the challenge at the moment. That is the reason why we have not seen this in production cars extensively.

Spark Plug Controlled Compression Ignition (SPCCI)

This technology was proposed to enhance the HCCI process by having some control over the timing of the ignition. This can be incorporated with the HCCI for high load/high-speed scenarios (when the accelerator pedal is pressed completely). Also, in case of cold starts, when the temperatures are extremely cold, the spark plug could aid the initial few seconds of operation until the components of the engine reach the ideal operational temperatures. This could combine the benefits of having much better control of the ignition timing and efficient engines.

Also read: What is Gasoline Direct Injection ? Why is it relevant in modern cars?

The more control we can have of the ignition timing, the better it is for the engine because all the parameters of the engines are related to the combustion/ignition process. This includes power and torque output, emissions, fuel efficiency, thermal efficiency and everything in between. We think that there is still some time until we can completely electrify our mobility across the globe. Technologies like these will help us immensely until then to keep up with the increased requirements to adhere to the emission regulations from various bodies across the world. With a bit more research in this technology, we might actually see it in production cars fairly soon. Mazda’s Sky-Active engines are the ones that were supposed to use this technology. Maybe the engineers at Mazda are still working to perfect this technique so that there are no problems with reliability.

Also read: All you need to know about 4WD and AWD drive systems – What is a Differential?

Image Source: Researchgate