We are excited to bring another interesting theme from the world of automobile engineering your way. As usual, the aim of these articles is to give the readers an easy-to-understand guide to comprehend the technical aspects of automobile engineering. Many car enthusiasts want to know more about how the engine and various components of a car function in a simple language without getting into the depth of technicalities. Today, the topic of discussion is a very common one that you must’ve come across many times. We shall discuss the working and types of a cam assembly which includes cam profiles, camshaft, valves and the valve operating system. We shall try to understand each of these in simple terms. But before moving forward, make sure to check out Car Blog India for all the latest news from the world of the automobile industry and the Automobile Technology Section for all the technical articles from automobile engineering.

Also read: What is EGR (Exhaust Gas Recirculation) – Working, Principle & Advantages!

Camshafts – Purpose

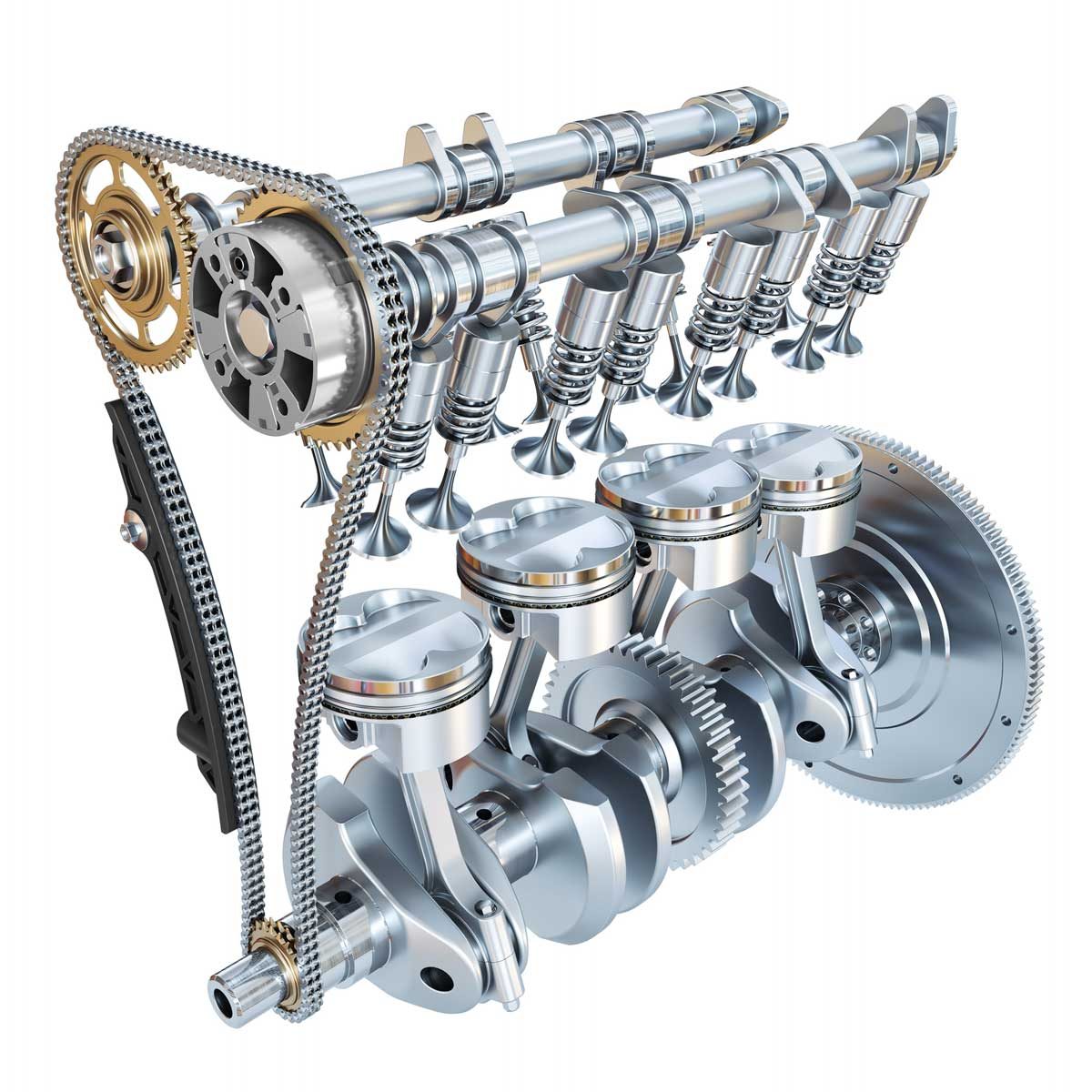

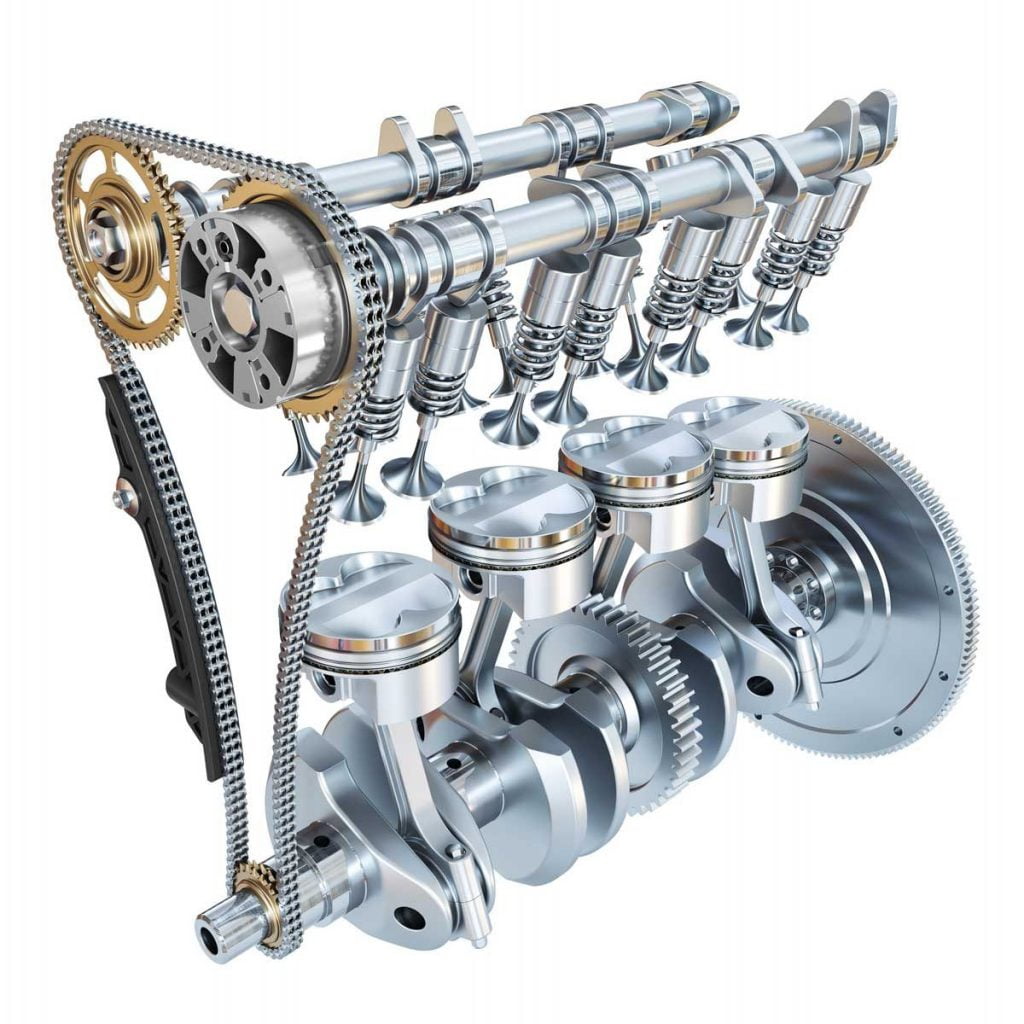

Camshafts are a part of the cam assembly that is found in every vehicle out there. These can range from very simple designs and functioning to highly precise and sophisticated setups depending on the type of cars. For the most part, the passenger cars will have a relatively simpler and efficient design setup and a performance car will have a highly sophistical and complicated setup. We are already aware of the four strokes that an internal combustion engine works on. These are the intake, compression, power and exhaust strokes. The intake and exhaust strokes make use of the intake and exhaust valves that are placed on top of the cylinder head. The purpose of these valves is to control the airflow in and out of the cylinder. We shall discuss the functions of the valves later. The valves are controlled by something known as the cam assembly. This includes a cam, camshaft, follower, lever or push road, springs, rocker arm, etc. The purpose of these is to make sure that the valves are operated according to the requirement of the driver.

Also read: Shift-by-wire, Steer-by-wire, Brake-by-wire – What are their functions?

Camshafts- Working

The camshafts rotate with the engine. The cam is mounted on the rotating camshaft and the follower is connected to the cam. Depending on the cam profile or the shape of the cam, the follower pushes the connecting rod or rocker arm which in turn pushes down the valves. That opens up the cylinder head and lets the fresh air enter or the combusted gases out of the engine. A very important component of this assembly is the spring. This spring actually ensures that after the valves have been pushed down, they can return to their original place quickly. The stiffness of the spring allows immediate shutting down of the valve which is necessary in order to prevent losing power after the intake stroke. If the valves remain open for a longer period of time, the compression stroke will get affected and the entire cycle will lose efficiency. Similarly, if the exhaust stroke remains shut for a longer time, there will be high pressure and temperature build-up which can even damage the valves.

Also read: Uses of a 48V hybrid system – Regenerative Braking, Turbo Boost, Fuel Efficiency and more!

Cam Assembly- Classification

Now, the requirements from the engines are increasing and people want fuel efficiency with high performance from their cars. Almost all these parameters depend on the control of airflow of the intake and exhaust. Depending on that, the efficiency of the engine, the power and torque output and the emissions are affected. Therefore, with electronic controls these days, the need to have a responsive cam system is of utmost importance. As a result of that, there are various types of cam profiles to enable the Variable Valve Timing and Lift to offer flexibility. Depending on the need of the driver, cam profiles can be switches wherein the duration and lift of the valves can be controlled. Various kinds of cam profiles include Radial Cam, Cylindrical Cam, Wedge Cam, Conjugate Cam, Globoidal Cam and Spherical Cam. These have various characteristics of wear and tear, efficiency, maintenance and such things. For instance, a regular car might have a cam profile that can be switched between two different positions and a performance car may have an electronic assist that can vary the cam profile infinitely within the range of operation of the valve travel.

Also read: What are Intercoolers? What are their types and functions?

Valves- Purpose and Working

Now, we move on to the valve assembly inside the engine of a car. As mentioned previously, valves are responsible for letting the fresh air and fuel into the cylinder, as well as making sure that the exhaust gases are removed from the cylinder after the combustion stroke. These valves open and close 10 to 30 times in a second and therefore, the components must be very responsive and precise. If one cycle fails, that will affect the entire combustion process. As a result, there will be a loss of power or worse. There are differences in valve sizes and materials within one car as well. The intake valves are generally larger than the exhaust valves. This is because it takes a lot of energy to pull in the fresh air compared to pushing out combusted air out. The pressure by the pistons makes sure that the exhaust gases are thrown out quickly and the need for a larger surface area is therefore not needed. Similarly, the valves on the exhaust side are exposed to higher temperatures and pressures compared to the intake side. Therefore, to facilitate quick and precise action, valves are used.

Also read: What is Engine Braking? How does Cooling System work?

Valves are made of different materials depending on the type of operation. Also, in performance cars, every gram counts and therefore, the weight of the valves can also be altered. In such situations, the valve is hollow and made up of stronger materials to resist more heat and pressure. The temperature on the exhaust sides can be extremely high and therefore, that side can use valves made up of expensive material compared to the intake valves. Depending on whether a car has port injection or direct injection of fuel, there cold be carbon deposits on the valves which require regular cleansing.

Also read: What are Catalytic Converters? How do these reduce emissions?

Image Source – Family Handyman