In this edition of Automobile Technology content, we focus on the types of chassis used in vehicles: Monocoque, Ladder Frame, Backbone and Tabular. These are the major chassis that have been used in cars for a long time. As a matter of fact, over 90% of vehicles, today, have a Monocoque construction due to various benefits it offers. But are still distinctive requirements where the other types of chassis frames are used including the Ladder frame, Backbone and Tabular. So, what are the differences in the construction and application of various chassis, let us take a look in detail.

Also read: What is Hydrogen Combustion Engine – Pros and Cons!

Types of Chassis Frames

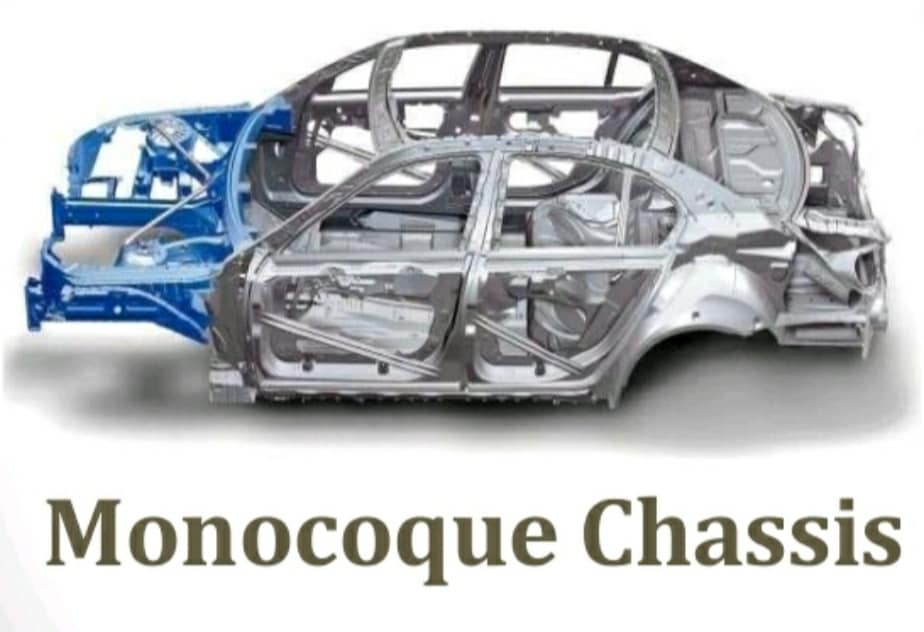

Monocoque

Let us start with one of the most common types of chassis frames used in almost all automobiles today, the Monocoque Chassis. The construction of a monocoque chassis is quite simple in the sense that the entire structure is one big construction. All components or mechanical parts constitute the frame, foundation and body of the car. The engine, gearbox, suspension, seats and exterior body panels are simply attached to the construction. This means that the overall construction is very lightweight and compact. There is quite a lot of safety element to it. The applications include all sorts of everyday vehicles ranging from small and compact hatchbacks to large and heavy SUVs. It must be noted that modern SUVs are using monocoque construction quite a bit which was not always the case in the past. There are many characteristics of such a type of construction.

Also read: Types of Sensors in a Car – Air, Speed, Knock, Parking and more!

Advantages and Disadvantages

- Lightweight and compact construction allow for the usage even in the smallest of cars.

- The handling qualities are greatly enhanced because the entire vehicle is one compact structure and dynamic forces are easily transferred out to maintain stability around the corners.

- Being used extensively, the cost of manufacturing is quite low, which is why it could be used for any car.

- The safety aspect of the car and passengers is enhanced because of a cage-like construction. A lot of crumple zone can be added to the construction.

- Being light, it ensures higher fuel efficiency which makes the usage in budget cars prominent.

- Some of the disadvantages include a lack of off-roading capabilities because of stiff construction.

- The vehicle doesn’t have too much agility because there is no room for movement of components as in the case of ladder frame chassis.

- Only affordable if produced in large quantities (mass-production).

Also read: What are SOHC, DOHC, OHV – Advantages & Disadvantages of each!

Ladder Frame Chassis

The second-most popular type of chassis is the ladder frame chassis. A lot of people know about this because of its heavy usage in SUVs, particularly the off-roading capable SUVs. SUVs in India like the Fortuner, Endeavour, Thar, Gurkha are some of the most common large SUVs with quite impressive off-roading capabilities. This is possible only because the cabin of the SUV is separated from the chassis. The chassis is constructed separately and the body is attached to it later on. This adds another layer between the cabin and the road. These chassis are generally accompanied by an All-Wheel (or 4 Wheel) Drive System. Following are the characteristics of a ladder frame chassis.

Also read: Front, Mid and Rear Engine Cars – Pros and Cons of each!

Advantages and Disadvantages

- Ladder Frame construction is universal, in the sense that various kinds of bodies can be attached to one kind of ladder frame.

- Being separately movable from the body, the off-roading capabilities are enhanced and as the suspension could travel further and almost independently of the body.

- These chassis are incredibly agile and flexible.

- The cabins are generally quieter because the chassis insulates the body and the ride quality is better.

- Some disadvantages include poor handling due to increased height and separation from the ground.

- Heavy components mean that they can’t be used in cars and performance vehicles.

- Generally a bit expensive.

It must be noted that the usage of Monocoque and Ladder Frame Types of Chassis is completely different and together they constitute almost the entire type of vehicles that are produced today.

Also read: Main Components of a 4-stroke IC Engine – Pistons, Valves, Turbos, Camshafts and more!

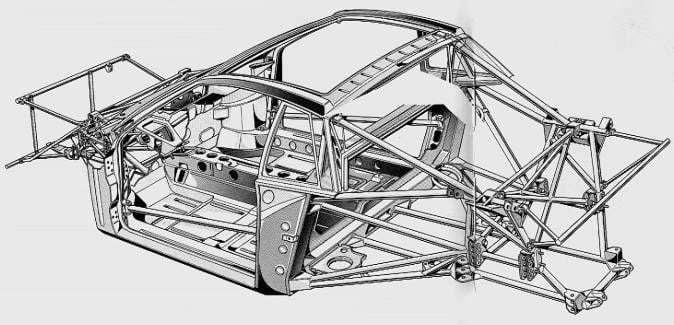

Tabular Chassis

These are the most used types of chassis frames in racing cars. You must’ve seen that in the racing cars, all the interiors are removed and the entire vehicle is constructed in a cage-like manner (even on the inside). Since the entire vehicle is covered with a thick network of tabular pipes, it is known as the Tabular Chassis. Following are the characteristics of such type of chassis.

Also read: Working of Roots, Twin-Screw & Centrifugal Superchargers – Advantages & Applications!

Advantages and Disadvantages

- Due to the dense pipes, the construction is lightweight and more rigid.

- Since these are 3 dimensional in nature, the overall safety is higher in comparison to regular monocoque construction.

- One of the major disadvantages is the lack of practicality.

- One can’t use this type of structure for day-to-day cars.

Also read: Working of Synchronous and Induction Motors in Electric Cars!

Backbone Chassis

The Backbone Chassis is probably the one that not a lot of you have heard of. It is because this is a very peculiar kind of construction that was used back in the day. Although, some modern cars still use this chassis. The construction includes a rectangular cross-sectional tube connected to both, the front and the rear axle shaped like a spine in humans. The driveshaft is neatly tucked under this backbone and kept safe from getting damaged. The drivetrain and engine are attached to the ends of this tube. Following are the characteristics of such type of chassis design.

Also read: Working of Electric, Hydraulic and Electrohydraulic Power Steerings!

Advantages and Disadvantages

- Such a type of construction allows for a better connection of the axles to the ground. This enhances the stability of the car.

- In the case of off-roading, the drive shaft is quite safe even if the car hits the ground often.

- The rigidity is also higher and can withstand a lot of pressure.

- Disadvantages include difficulty in repairing the drive train as the entire backbone has to be opened up.

- The manufacturing cost for the backbone chassis is high which makes the car more expensive.

From the explanation above, it is quite evident that the most common types of chassis frames are the monocoque and ladder frame chassis which are widely used today depending on the application.

Also read: What is EGR (Exhaust Gas Recirculation) – Principle and Advantages!