In this edition of Automobile Technology Content, we bring to you the overall construction and components of a regular internal combustion engine. The aim is to give a brief idea of the construction and working of all the components inside an engine. All this will be done in a simple-to-understand language so that one develops an interest in knowing about the various processes taking place inside an internal combustion engine. If you are interested in such articles, do follow Car Blog India and visit the Automobile Technology Section directly for some interesting technical processes related to automobile engineering in simple words. Let us dive into this one for now.

Also read: What are Torque Vectoring, Torque Steer, Understeer & Oversteer?

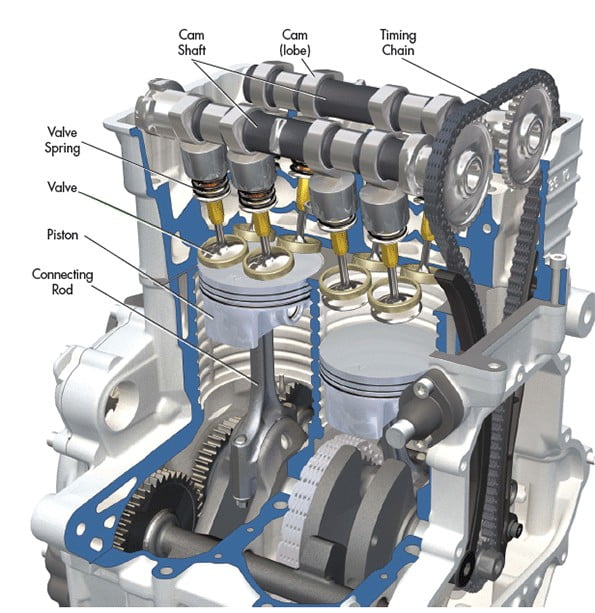

4-Stroke Internal Combustion Engine

Almost all the cars that we have today, follow the principle of a 4-stroke cycle. These represent Intake, Compression, Power and Exhaust strokes. If we have to explain briefly about each of these, we shall begin with the intake stroke which consists of filling the combustion cylinder of the engine with fresh air. A combustion chamber is where the fuel is burnt to produce the energy required to enable the motion of a vehicle. Oxygen is necessary for combustion and therefore the intake stroke ensures an adequate supply of fresh air (oxygen) to burn the fuel. The second stroke represents the compression phase. This means that the air and fuel have to be compressed or mixed together so that the combustion or the burning process takes place cleanly. It must be noted here that if there is some fuel which has not been mixed thoroughly, it will come out of the exhaust as unburnt and cause massive pollution. Therefore, the mixing of air-fuel is an important aspect of internal combustion engines.

Also read: Working of Synchronous and Induction Motors in EVs (Electric Cars)!

Thereafter, the burning of air-fuel mixtures causes the release of energy which propels the car forward. This is the process where the energy of petrol or diesel is actually released in the form of heat and gets translated into mechanical energy or motion. The final stroke is the exhaust stroke, which makes sure that the burnt gases and particles are safely removed from the engine and released into the atmosphere. It must be noted that there is an exhaust gas treatment system attached to the exhaust which makes sure that the toxicity of these gases is minimum before releasing it into the atmosphere. These 4 processes constitute 1 cycle, which means that every cycle has 1 power stroke.

Also read: Working of Roots, Twin-Screw, Centrifugal Superchargers!

Valves

The process of controlling the air or gases inside various parts of the engine is taken care of by the valves. The valves are present at the intake side of the engine to let in the fresh air in the required quantity. Valves are also present at the exhaust side to enable the necessary amount of exhaust gases to be thrown out of the engine. Also, these are essential components in other equipment like a turbocharger, pump or other mechanical devices. Closing and opening operations are performed by these valves within various devices.

Also read: 6 Most Relevant Connected Car Tech Features in Modern Cars!

Camshafts

It is a mechanically designed component, which has the elevations on the shaft to open and close the intake and exhaust valves. When the camshaft rotates, these elevations push the parts connected to the valves and achieves the closing and opening operations. The duration and timings of opening and closing of valves can be controlled or varied through the specific designs of the camshafts. Depending on when the intake valves open, the fuel injection inside the cylinder takes place to ensure the proper mixing of the fuel with the air.

Also read: Working of Hydraulic, Electric & Hydroelectric Power Steerings!

Pistons, Connecting Rods and Crankshafts

The entire energy of the combustion chamber has to be transferred to the wheels to enable vehicular motion. This requires some additional components to convert the reciprocating motion of the pistons inside the cylinder into the rotational motion of the wheels. Pistons are what move up and down inside the cylinder to generate the intake, compression, power and exhaust strokes. These are the moving parts inside the cylinder. These are connected to the connecting rods at the bottom, which make the crankshaft rotate. The crankshafts are connected to the drive shaft which, in turn, are connected to the wheels. In this way, the up and down movement of the pistons is converted to the rotational motion of the wheels. One complete revolution of the crankshaft comprises of 2 power strokes. Essentially, one can conclude that the chemical energy of the fuels is converted into the kinetic energy of the vehicle through this 4-stroke cycle using the abovementioned components.

Also read: What is EGR (Exhaust Gas Recirculation) – Principle & Advantages!

Differentials

Differentials are mechanical components that receive the power and torque from the engine and divide them equally (in the case of 2WD) between the wheels. In the case of a 4-wheel-drive system, the differentials allow disproportionate amounts of torques to any of the four wheels which requires it the most. The main aim of the differential is to allow for different speeds of different wheels. For instance, around a corner, the outer wheels of a car have more distance to cover compared to the inner wheels. To maintain stability, these wheels have to move at different speeds, which is ensured by the differential. More sophisticated off-road cars, in particular, have multiple differentials to offer flexibility with regards to which wheels should receive how much torque. This depends on the amount of traction that a particular wheel has.

Also read: How do ABS, EBD, Brake Assist, Hill-Start Assist, Traction Control and ESP work?

Turbos and Intercoolers

Essentially, one can think of turbochargers and intercoolers as performance enhancers of the vehicles. These have specific purposes which act as a catalyst for more power, reduced emissions, fuel efficiency or thermal efficiencies. A turbocharger enhances the power and torque of a car by using the energy of the exhaust gas. The exhaust gases make the turbine of the turbo to rotate which rotates the compressor that is mounted on the same shaft. This causes the fresh air to compress and the quantity of fresh air that can be packed inside the cylinder is increased. This enables more fuel to be injected into the combustion chamber which equals more power. Intercoolers make sure that the temperature of the entire system (or fresh air) remains low. Especially, after the compression of air, the air becomes hot and needs to be cooled down before entering the combustion chamber. The higher temperatures cause higher NOx (Nitrogen Oxides) which need to be under a limit to be street legal. The emission aspect is enhanced.

Also read: What is Air Suspension – Uses of Soft and Stiff Springs!

Exhaust Gas Treatment System

Lastly, the exhaust gases out of the engine are treated in the exhaust system of a vehicle. The emissions norms and becoming stricter day by day and the internal combustion engines need to be more efficient and clean to continue. Therefore, the exhaust treatment systems make use of modern technology which is developing day by day to make sure that the amount of pollution caused by the vehicles remains the allowed limit. Since these limits keep decreasing with every new emission regulation, exhaust gas treatments keep becoming more sophisticated.

Also read: What is Engine Knock – Consequences and Prevention!

Image Source: Machine Design