In this edition of Automobile Technology content, we have come with another very interesting and technical theme, known as the EGR or Exhaust Gas Recirculation. In this section, we try to find out the complex technologies related to automobile engineering and explain the principle, working and advantages of that technology in a simple to understand language. This is primarily for those, who are interested in the working of automobiles and want to get the information quickly and efficiently. If you are someone like that, make sure to follow Car Blog India for all the latest news and scoops from the world of the automobile industry and Automobile Technology Section to read up on all the content related to complex technical processes, explained in a simple manner. Let us dive into the topic of EGR in detail in today’s article.

Also read: Shift-by-wire, Steer-by-wire, Drive-by-wire – Functions, Working and Advantages!

EGR – Exhaust Gas Recirculation – Principle and Need

As the term suggests, Exhaust Gas Recirculation refers to the redirection of the exhaust gases after the combustion process and use it to achieve various goals in the engine of the vehicle. This could range from controlling the temperature inside the combustion chamber to improving the fuel economy of a car and everything in between. As we know, the quality of air inside the combustion chamber, the ignition process, pressure and temperature inside the engine decide all the performance, fuel and emission parameters and output of a car, tweaking these could bring in a ton of benefits in all these regards. That is the reason why so much research has gone into these aspects and new technologies keep coming up as the emission and performance requirements keep on increasing. Governments are always bringing in tougher emission regulations to keep the environmental pollution in check and the customers are looking for more powerful or more fuel-efficient cars at the same time.

Also read: Uses of a 48V hybrid system – Regenerative Braking, Turbo Boost, Fuel Economy!

These are the reasons why coming up with new technologies to tackle all these issues is an absolute must. Because these technologies are becoming extremely expensive and the emission regulations are becoming stricter day by day, the industry is rapidly heading towards electrification. This includes hybrid and fully electric powertrains primarily to combat the issue of pollution and fuel economy. Granted, electrification is an expensive affair at the moment, but with time, the technology with becoming widely adopted and the volumes will increase reducing the cost substantially. We might eventually the same cost of the car powered by either electricity or an internal combustion engine. While that might be a bit far away, we will have to do with techniques like the EGR for now.

Also read: What is Air Suspension – What are Soft and Stiff Springs?

EGR – Exhaust Gas Recirculation – Working

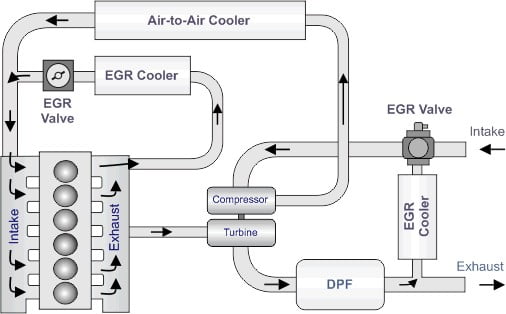

The working of this process is fairly simple but the implications are impressive. There is an EGR-valve fixed after the exhaust manifold and before the catalytic converter. This valve opens and redirects some of the exhaust gases back to the intake manifold, where these are mixed with fresh air. Once mixed, the concentration of the oxygen in the fresh air is reduced and the temperature of the fresh air is increased slightly. Now, the exhaust gases are inert gases because they have already been burnt and free oxygen is not present in the exhaust gases. Therefore, the Nitrogen in the air is not able to react with the excess oxygen and the formation of NOx (Nitrogen Oxides) is decreased. This is one of the most harmful gases in the exhaust of a car and is required to be controlled according to the emission laws. By being inert in nature, these gases prevent the combustion to reach high temperatures where all the harmful toxic gases are formed. Sometimes, an EGR cooler is also attached to the components before mixing it with the fresh air to reduce the temperature of the combustion further.

Also read: What are Intercoolers – What are their types and functions?

At high RPMs, the combustion process is very fast and the piston moves up and down quickly. This results in almost complete combustion which is efficient in every way. However, during day-to-day operation, an engine is not always at full load (accelerator pedal pressed completely) and hence, there are always free Oxygen molecules in the combustion chamber from the fresh air which have not been burnt. These give rise to Carbon Monoxide and NOx depending on the type of powertrain (petrol or diesel). The air-mass sensors decide how much exhaust gas should be supplied back to the intake manifold and that is how the system works.

Also read: Regular Fuel vs Premium Fuel – Should you use premium fuel in your car?

EGR – Exhaust Gas Recirculation – Advantages

Now, as mentioned before, there are a ton of benefits to incorporating this technology into vehicles. A lot of work has been done on this technology and it is a perfectly reliable technology. Many modern cars make use of this technique along with advanced components like the EGR cooler and sensors to take even more control of the exhaust gases. The main challenge in this is to keep a track of exhaust gas mass and recirculate according to the requirements. Once all this is achieved, there are plenty of advantages to EGR including reduced fuel consumption, controlling of temperature and pressure inside the combustion chamber, reduction of harmful and toxic pollutants and a ton more. In the case of diesel engines, the ignition lag is contained under low load conditions. There are not too many disadvantages to this technique but the one point of contention in the case of petrol engines could be engine knock. Because the temperature is slightly increased due to the addition of exhaust gases. Another aspect could be the addition of components and maintenance related to ti. So, one has to be careful about that. But apart from that, there are only benefits to this technology.

Also read: What is Engine Braking – How does Cooling System work?

Image Source – Dieselnet