We already know the four strokes of an internal combustion engine are the intake, compression, expansion/power and exhaust stroke. The intake stroke is responsible for bringing fresh and cool air into the cylinder. This is dependent on the amount of throttle input given by the driver. If the accelerator pedal is pressed fully, the entire throttle valve is opened and the airflow from outside is unrestricted. This is generally the scenario during quick overtakes or drag races, where the driver needs quick acceleration. The more air there is inside the cylinder, the more fuel we can inject into the cylinder and resultantly, more power we can make. This is how the intake stroke functions.

Also read: How does combustion work in an engine – Uses of Spark Plugs and Fuel Injectors!

The compression stroke compresses the air (in case of direct injection system) or air-fuel mixture (in case of port injection system) so that the air and fuel are thoroughly mixed with each other. That is required for complete and efficient combustion inside the cylinder. If the mixture is not thorough, there will be a lot of toxins and unburnt hydrocarbons in the exhaust. This will raise the emissions levels of the vehicle and can increase above the legal levels.

Also read: What are engine remapping, tuning and calibration – Should you remap your car?

The power stroke occurs when the air-fuel mixture is burnt and energy is released. This energy is what pushes the piston downwards and causes the vehicle to move. In the case of petrol engines, the air-fuel mixture is burnt with the help of a spark plug that causes a spark to ignite the mixture. In the case of diesel engines, the compression ratio is so high that the air-fuel mixture is burnt autonomously. Diesel fuel is more combustible than petrol fuel.

Exhaust Stroke

The exhaust stroke is the final stroke process of the combustion cycle and is responsible for taking out the exhaust gases which are left after the combustion process. This can be NOx, CO and unburnt particles. Because the internal combustion process, as a whole, is very inefficient, the exhaust gases consist of almost 60-70% energy that is otherwise wasted. To make use of this energy, there have been a lot of techniques developed over the decades. The most famous of them is turbocharging. Turbocharging, essentially, makes use of the mass flow of the exhaust gases to rotate the turbine, which is mounted on the same shaft as the compressor. This allows the compressor to pull in more air into the cylinder by compressing the air. Hence, more fuel can be injected into the system to produce more power and turbo boost. Depending on the type of turbocharger and sophistication of the technology, this boost can be spread over a wide range of engine RPM. That is the reason, you will find wide bands of the boost in luxury and performance cars.

Also read: Types of turbochargers – VGT, Twin-Scroll, Twin-Turbo, Sequential Turbo, E-Turbo!

Components of exhaust system

Let us quickly discuss the components of an exhaust system in a car and also their uses.

Also read: Types of suspension setups – MacPherson Strut, Double Wishbone and Leaf Spring!

O2 Sensor

The components of the exhaust system include the Oxygen sensor, which is placed immediately after the exhaust manifold. The purpose of this sensor is to measure the content of oxygen in the exhaust system because it will tell you whether the air-fuel mixture is rich (more fuel, less air) or lean (more air, less fuel). Accordingly, the data will be sent to the ECU (Engine Control Unit), which will send out commands to alter the amount of fuel injected according to the need.

Also read: Types of clutches – Dry, wet, single and multi-plate along with advantages of each!

Catalytic Converter

After the O2 sensor, the most important aspect of the exhaust system is present, namely the Catalytic Converter. The function of the catalytic converter is to get rid of all the toxin exhaust gases from the engine, for example, NOx and CO. It converts these gases into CO2 or Nitrogen components which are less harmful to the environment. Another O2 sensor after the catalytic converter helps in determining the efficiency of the catalytic converter.

Also read: Disc Brakes vs Drum Brakes!

Resonator

Next to the O2 sensor is the resonator. A resonator is designed to prevent the engine from getting too loud in a particular RPM range. For example, on the highway, if the car keeps making loud engine sounds, it will be irritating to bear that sound for hours of driving. To avoid this, the resonator is designed to specifically tackle particular engine RPMs (for example, “Cruising RPM Range”) by making the sound waves collide with one another inside the resonator and cancelling the effects of each other.

Also read: What is Direct Injection Technology – Why is it so important in modern engines?

Muffler

Lastly, there is a muffler attached to the end of the pipes of the exhaust systems. This muffler is helpful in reducing the noise levels across the entire operation of the engine. This means, that throughout the entire engine RPM range, the levels of noise are controlled by the muffler.

Exhaust Scavenging

These are all the major components of the exhaust system. Now, let us move on to the clever technologies introduced to make maximum use of exhaust gas energy. The most famous of them all, after turbocharging technology, is exhaust gas scavenging. Let us look at it in detail.

Also read: All you need to know about 4WD and AWD Systems – What is a Differential?

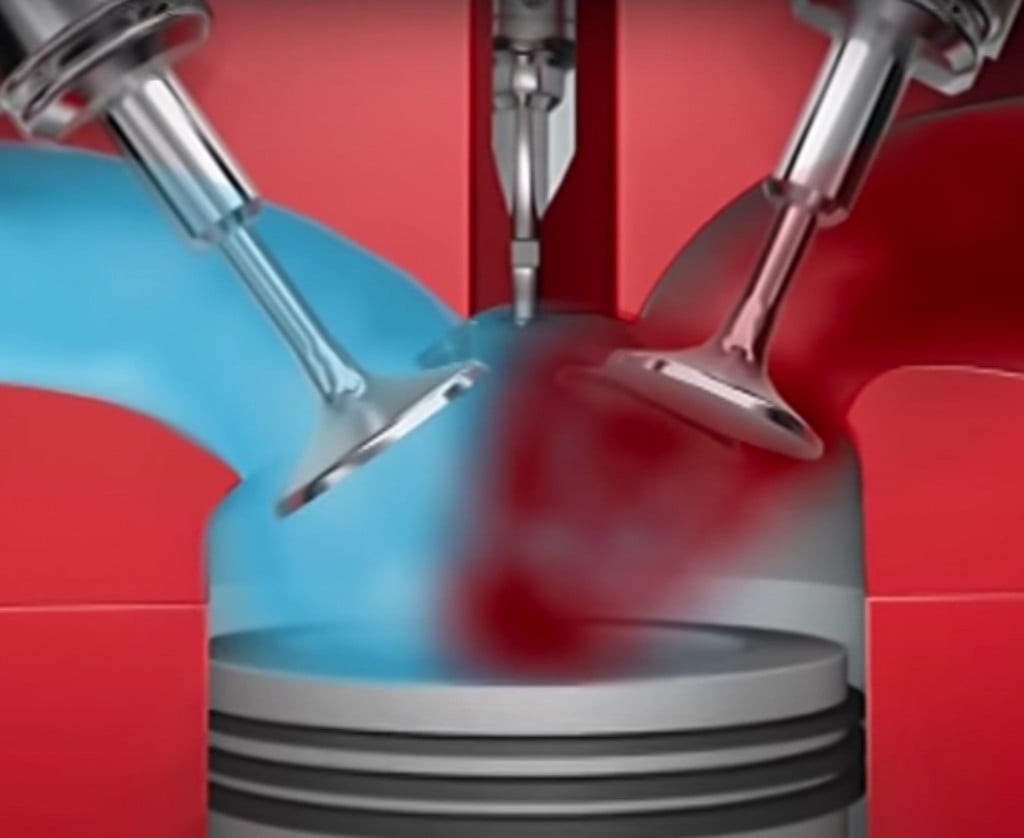

When the exhaust gases are pushed out of the cylinder by the piston through the exhaust valves, it creates a certain vacuum (or low-pressure area) in the exhaust manifold (or pipe). Depending on the diameter of the exhaust manifold and the velocity of the exhaust gases, the vacuum (or low-pressure area) created behind the exhaust gases is determined. There must be an ideal manifold length and diameter to strike a balance between velocity and back pressure caused by outside conditions. For example, if the pressure outside is high, the exhaust gases will not move from cylinder to outside and that will cause inefficient combustion in the next cycle. That is not good for the engine at all and can even lead to damaging engine components due to excess heat. Therefore, to make use of this low-pressure area behind the exhaust wave, the exhaust and intake valves are kept open simultaneously for a very brief amount of time. As a result of this, the fresh and cool air coming from the intake side (high-pressure area) into the cylinder, causes the exhaust gases to push out (low-pressure area) of the engine completely and the cylinder is filled with only cool air. If the exhaust gases stay inside the cylinder, the temperature for the next cycle is increased and the emissions, efficiency and fuel economy are affected negatively. This process is known as exhaust scavenging and is helpful in engine cooling and improved low-end torque by allowing more fresh air inside the cylinder resulting in more boost.

Also read: Battle of Transmissions – Manual vs AMT vs CVT vs DCT vs Torque Converter vs iMT!

Effects of Exhaust Scavenging

The positive effects of exhaust scavenging can be used in combination with direct injection technology, turbocharging and variable valve timing. This results in perfect control of all the variables to achieve the best results across a wide range of RPM. The torque curve covers a wider engine RPM range and allows higher torque even at lower engine speeds.

We hope that you like the automobile technology content. If you want to read more about such technologies related to Internal Combustion Engines, here are all the other posts from Car Blog India.