A clutch, as most people think, is not the pedal that is found at the left side of the brake, but a mechanical component in the transmission mechanism. The power is produced in the engine and is transferred to the wheels via the transmission. The purpose of having a gearbox/transmission is to efficiently transfer the power and torque to make the vehicle move. The power should be more than the force of resistance of a vehicle. The clutch is used to connect or disconnect the driving shaft from the engine shaft. It either connects or cuts the power supply from the engine. Let us look at the type of clutches generally used in automobiles.

Also read: What is Gasoline Direct Injection – Why is it relevant today?

Dry Clutches

As the name suggests, the clutch plate used in such mechanisms is dry. The plate consists of friction packs, which are placed in the plate itself. This develops the coefficient of friction and causes the plates to move. When the clutch is engaged, the clutch plate is detached from the engine shaft and the power supply is disconnected. This is done in order to change the gear according to the speed and conditions on the road. These are generally placed outside, exposed to the atmosphere.

When the driver releases the clutch pedal, the clutch is disengaged and the driveshaft and the transmission shaft are connected. Therefore, the power supply is connected again the power/torque is multiplied according to the gear that the vehicle is in.

Also read: All you need to know about 4WD and AWD – What is a Differential?

Advantages and Disadvantages of Dry Clutches

- Because of the lack of lubricant involved in the operation, the transmission efficiency is high.

- Power loss is minimal due to relatively direct contact with the clutch plate and driving shaft.

- Dry clutches are ideal for low-torque scenarios.

- Because of lack of lubrication, the wear and tear and noise is very high.

- The maintenance process and costs are high.

- Dry Clutch plates can not be used in high-torque scenarios.

- The life cycle is relatively short in comparison to the wet clutch mechanism.

Also read: Different types of transmissions – DCT vs CVT vs Torque Converter vs AMT vs iMT!

Wet Clutches

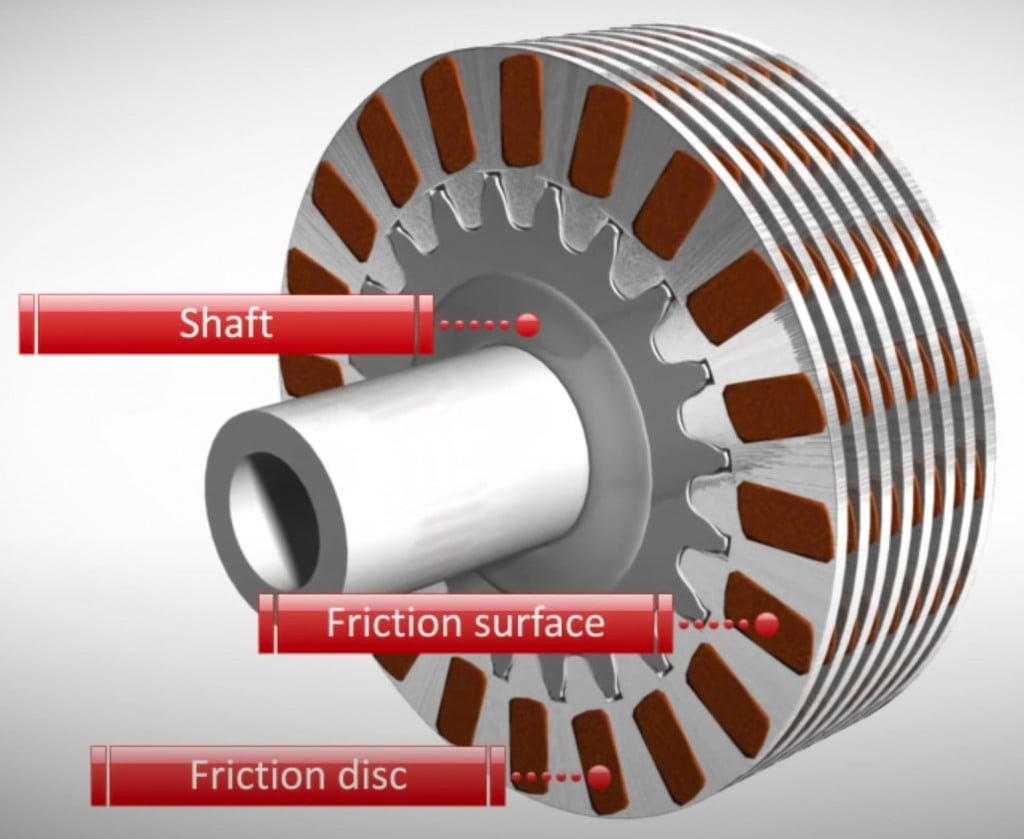

Wet clutches operation with a working fluid, the engine oil. The clutch plates (generally multiple plates) are bathed in engine oil for operation. The engine oil also works as a lubricant for smooth operation. In the case of wet clutches, there are multi plates to compensate for slippage between the plates sometimes. This system is used in high torques scenarios because of the nature of this setup. It is placed inside because it has to be soaked in oil.

Also read: Types of suspension systems – MacPherson Strut, Double Wishbone and Leaf Springs!

Advantages and Disadvantages of Wet Clutches

- Lubricant enables more abuse, the wear and tear are less.

- High torque scenarios can be achieved because more beating is allowed in a wet clutch system.

- The dust particles are removed because of the oil filter.

- The life cycle is more than the dry clutch.

- The noise levels during the operation are very low.

- High coefficient of friction due to more number of plates.

- The efficiency of power/torque transfer is reduced due to the presence of fluid between the plates.